The new generation of VCI

Handling and packing of VCI film

- Cleaned metal surfaces provide the best protection

- Room temperature during the first 12 hours is preferable

- The film should not be more than 30 cm away from VCI foil for optimal function

- If there are large air spaces, desiccants should be used

- Always strive for an airtight packaging

Note! When the products are unpacked, the VCI protection disappears.

Storage of film

- Indoor storage <30°C

- Well-packaged, as airtight as possible

- VCI foil can be used up to 1 year when well-packaged

VCI and corrosion

VCI stands for Volatile Corrosion Inhibitor and is a method used to protect metals against corrosion. Corrosion/oxidation is a chemical erosion where materials, especially metals, dissolve through a chemical reaction. Corrosion occurs when metals react with oxygen and moisture. To prevent corrosion, one needs to either eliminate oxygen and moisture, or protect the metal from oxygen and moisture.

Corrosion is rooted in the molecular structures of different materials; metals are created from various minerals such as iron oxide or limonite. The metal then becomes less stable than the original mineral, causing the metal to break down into a more stable compound similar to the original mineral. Corrosion can occur in environments with both air and water, as well as in chemical solutions.

To protect metal against corrosion, there are several methods and materials, such as through oils/greases, coatings, or as in this case, with the help of VCI film.

What is VCI and how does it work?

VCI additives are substances with high vapor pressure.

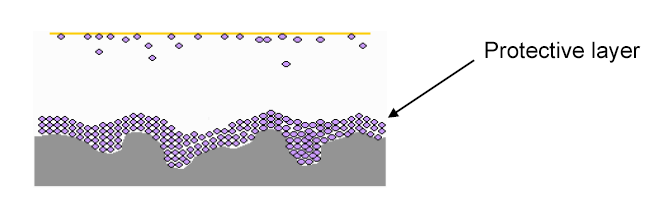

VCI forms "protective ions" along with moisture. These ions are attracted to the metal surfaces and form a thin layer on the surface of the metal. The film prevents oxygen and moisture from reaching the metal, thereby preventing or minimizing corrosion and rust formation during storage and/or transportation.

When the products are unpacked, the VCI protection (ions) disappears.

Environment, manufacturing, and health

PacsOns VCI film is nitrite- and amine-free, as well as free from heavy metals, phosphates, and halogens. Our VCI film contains nothing considered harmful to health, and it is food-approved for most applications. The film can be both material and energy recycled.

The product is manufactured in Sweden by Draken i Reftele AB.